About Fiber Glass

Reinforcing materials like fiberglass and carbon fiber are mixed with compounds like epoxy and polyester resins mostly applied in composite materials, they are cured through heat reaction. Advantages of these materials are very numerous and raw materials processed through pultrusion remain very competitive, it is an economical option comparing to other materials as iron or steel. Products made through GFRP (fiberglass reinforced plastic) are chemical, corrosion, UV and weather resistant, material has an excellent ratio cost/performances, it has low weight with higher strength, making it very robust, it is not magnetic , it is easy to assembly for structural shapes and profiles, it has in addition lowest cost concerning maintenance. List of properties is really vast and makes GFRP as versatile choice with optimum cost efficiency, it is also employed for operating conditions between temperatures from -100ºC to +180ºC and it is self-extinguishing and halogen free. It is likewise thermal and electrical insulating, material is really competitive in relation to metals.

We propose standard products like rods, tubes and profiles with many shapes available in standard diameters from small and medium quantities but there are many products which can be produced through pultrusion process. Main items are ladders, handrails, fences, grilles, walkways for industrial area. U profiles are mainly focused for platforms, sewage plants and supporting structures and we also have suitable safety floors with the motive to supply solution for cover applications at lowest weight, there are some standard colors, they are made with content of 35% of fiberglass and polyester resin, we can supply faster some structures and shapes with standard requirements. We are good willing to reply to your requests or any information you might need regarding any project or to compare and to substitute other materials with objective to be the most competitive option. Available products cover a wide range of applications for many sectors and allow us to provide short lead time.

Fiber Glass Tube

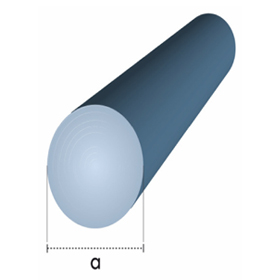

Fiber Glass

Rods

Products Table

a (mm) |

secc. (mm2) |

weight (gr.) |

|---|---|---|

| 2 | 3 | 6 |

| 3 | 7 | 13 |

| 4 | 13 | 23 |

| 4,5 | 16 | 29 |

| 5 | 20 | 35 |

| 6 | 28 | 51 |

| 6,1 | 29 | 53 |

| 7 | 38 | 69 |

| 8 | 50 | 90 |

| 9 | 64 | 115 |

| 10 | 79 | 141 |

| 11 | 95 | 171 |

| 12 | 113 | 204 |

| 13 | 133 | 239 |

| 14 | 154 | 277 |

| 15 | 177 | 318 |

| 16 | 201 | 362 |

| 17 | 227 | 409 |

| 18 | 254 | 458 |

| 19 | 284 | 510 |

| 20 | 314 | 565 |

| 22 | 380 | 684 |

| 25 | 491 | 884 |

| 30 | 707 | 1.272 |

| 32 | 804 | 1.448 |

| 35 | 962 | 1.732 |

| 39 | 1.195 | 2.150 |

| 40 | 1.257 | 2.262 |

| 45 | 1.590 | 2.863 |

| 50 | 1.964 | 3.534 |

| 55 | 2.376 | 4.277 |

| 60 | 2.827 | 5.089 |

| 65 | 3.318 | 5.973 |

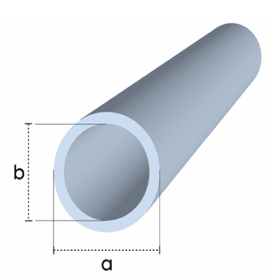

Tubes

Products Table

a (mm) |

b (mm) |

sec. (mm2) |

weight (gr.) |

|---|---|---|---|

| 3 | 16 | 19 | 34 |

| 4 | 6 | 14 | 25 |

| 4 | 8 | 35 | 62 |

| 5 | 10 | 55 | 99 |

| 6 | 10 | 50 | 90 |

| 6 | 12 | 80 | 144 |

| 8 | 12 | 63 | 113 |

| 10 | 15 | 106 | 191 |

| 10,5 | 15 | 94 | 170 |

| 15 | 20 | 185 | 332 |

| 18 | 24 | 283 | 509 |

| 20 | 25 | 287 | 516 |

| 20 | 40 | 1037 | 1866 |

| 25 | 30 | 412 | 742 |

| 27 | 32 | 465 | 837 |

| 30 | 35 | 562 | 1011 |

| 32 | 39 | 742 | 1336 |

| 35 | 40 | 734 | 1322 |

| 40 | 45 | 962 | 1732 |

| 40 | 60 | 2136 | 3845 |

| 45 | 50 | 1080 | 1944 |

| 53 | 60 | 1579 | 2842 |

| 63 | 69 | 2156 | 3881 |

| 70 | 90 | 4438 | 7988 |

| 80 | 100 | 5404 | 9726 |

| 90 | 100 | 5027 | 9048 |

| 100 | 125 | 8738 | 15728 |

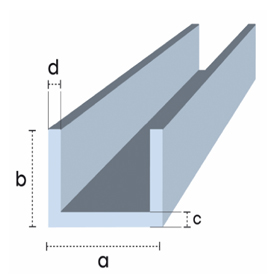

U Profile

Products Table

a (mm) |

b (mm) |

c (mm) |

d (mm) |

|---|---|---|---|

| 40 | 20 | 3 | 3 |

| 60 | 30 | 5 | 5 |

| 70 | 30 | 4 | 4 |

| 120 | 28 | 4 | 4 |